This project consist of making a copy of the TRW-17 from Eminent Technology to reproduce sound in the infra-range, between a few Hertz up to 30Hz ideally.

First prototype

The design of the first prototype is loosely based on different experiment we've been able to find on internet, mainly from this playlist of videos:

We used a Beyma 10CMV2

(datasheet).

It was chosen for the Xmax and Xdamage that are respectively 6.5 and

30mm, which is nice to have to experiment for rotating the blade using a

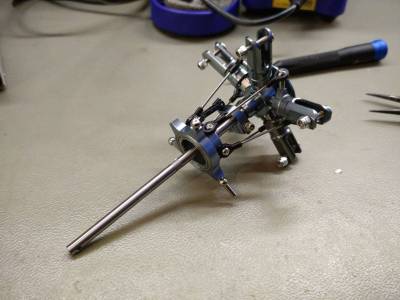

RC helicopter rotor

head.

In this design, the rotor head has to go through the speaker vent (the hole on the bottom of some big speaker to cool it down).

The problem is that the Beyma 10CMV2 vent is 4mm in diameter, whereas the rotor head shaft diameter is 5mm. Thus, we wouldn't recommend using exactly this speaker, but couldn't really recommend any other without having to buy and check the diameter of the vent since it's rarely given by the manufacturer.

Let's start by cutting the cone out:

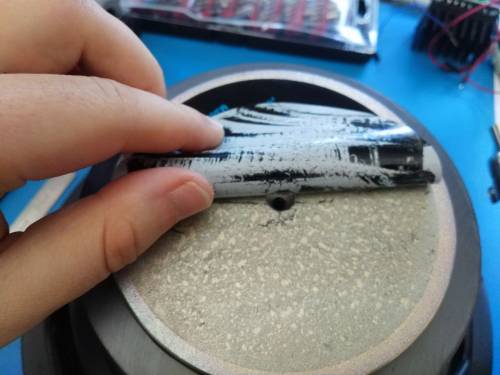

To deal with the problem of the vent, we removed the spider and drilled the vent larger, and took the opportunity to insert some ball bearings to make sure the shaft stays coaxial and doesn't touch the magnet.

Also we put some masking tape before and after drilling to make sure the metal dust won't stay stuck in the air gap between the voice coil and the magnet, which is a pain to clean up. The dust won't go very far away from the drill center since there is quite a strong magnetic field keeping them around, so no need to cover everything usually. Wouldn't recommend going through that mess, but hey that's the first proto.

Then we cut the cone structure that we don't need anymore and that would interfere with the blades later on:

Ang glued the rotor head to a cut (enough to re-attach the rotor head arms) bottle cap (50cL FuseTea Lemon if you're crazy enough to follow our steps that closely), aligned the voice coil/spider assembly with some paper (cut multiple strips, put a 3 stacks of a few layers like shown below until it fits nice and tidy), and glues the spider back onto the metal structure (and remove the paper once dry obviously):

Wobble wobble time! (0-20Hz chirp from a signal generator without amplifier, so the amplitude is quite low)

The design of the holder for inserting the blades in the rotor head is available here on OnShape. It's been printed on a super cheap resin 3D printer and fits quit well.

The blade design is available here on OnShape. It's basically the blade shape from the paper "The rotary subwoofer: A controllable infrasound source" (archive.org) with an extension to fit into the holder. It's been cut into 5mm plywood which might be a bit too thick and not rigid enough, but that's what we had available for quick testing.

More wobble? More wobble!

The motor used here is a cheap 250W CNC motor that was laying around (looks like a DC controlled brushless) that is rated for 12k RPM. We've read that spinning at least at the same frequency as the top of the audio bandwidth would reduce the distortion. Not sure if it's true, but getting up to 30 Hz would require spinning at least at 1800 RPM, so we got plenty of margin with this motor.

At the moment we're just adjusting the voltage to set the speed, which might vary depending on the modulation of the blades, but we didn't try to measure any variation yet. We got a less cheap-ass 250W brushless with a VESC-compatible controller that we still need to try.

To fix the rotor head shaft into the motor, we're using a 5mm ER11 tool holder that fits into this particular motor, your mileage may vary. Since the shaft is not going too much far outside of the back of the speaker, the tool holder is touching the inside of the ball bearing on the back which is not really a problem since the whole thing is spinning together anyway.

To Do

- Test new brushless motor

- Make structure to hold the whole thing

- Try different blades

- Replace rotor head to reduce mechanical play (see this, similar to the TRW-17)

Material

* Beyma 10CMV2 * RC helicopter rotor head * 250W 12k RPM CNC motor